Recently published

The german magazine "Giesserei" of the Bundesverbandes der deutschen Gießerei-Industrie reported in detail about inMold in one of the last issues.

Read articleHow can you efficiently plan your mold design while saving time and money with inMold.

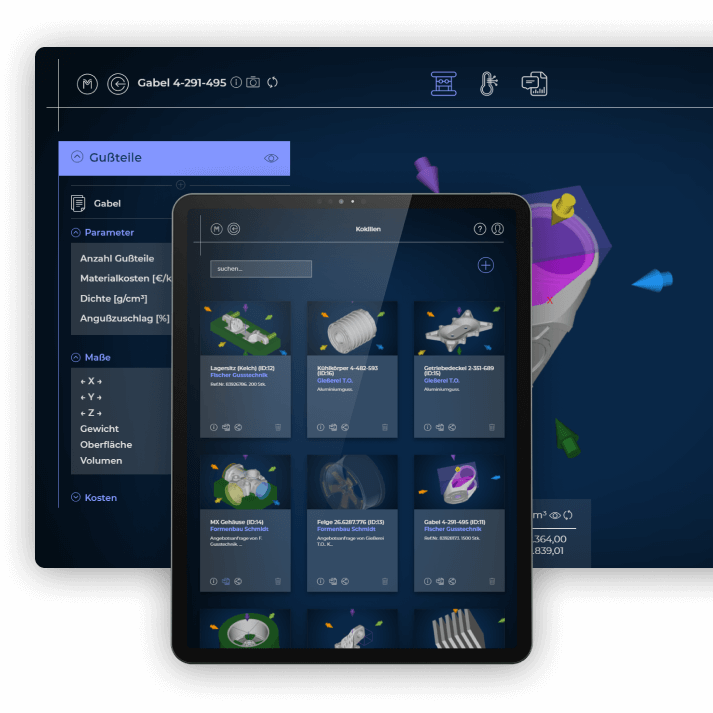

The inMold planner gives you the possibility to identify and communicate potential problems quickly and effortlessly, from the very beginning of the mold construction process. It saves important resources and promotes cooperation between everyone involved in the process. Via our web-based, to-go solution, foundries, cast part customers and mold makers, can work together and cooperate to optimize the casting mold. This simple, data-safe collaboration avoids costly coordination cycles, as well as, software and license handling. All this to make finding offers more transparent and cost-efficient.

inMold provides fast and precise estimation of the necessary workload and costs by providing tools for detecting cores, preselecting sliders and checking demoldability. inMold combines all these and many other functions to ensure the most efficient tool-planning process.

Thanks to inMold’s intelligent online hotspot analysis, important properties and functions such as pourability, feed or pouring position, can be reliably and quickly checked. In this way, we can identify potential obstacles in advance and further optimize the geometry of the cast.

inMold enables an interactive and constructive project coordination between all participants. The exchange between foundries, mold builders and designers is simplified by clear tools for communication, task allocation and reliable documentation of the project agreements. This not only enables secure data exchange, but also makes agreements more efficient.

The construction of molds requires a lot of knowledge, imagination and experience. Read how inMold supports its customers with smart but simple solutions:

As an inMold registered user, you may create your own projects, upload your own geometries to support your offer-founding process and use the full range of functions.

In order to make your decision easier and show you how quick and accessible inMold, the planning tool, really is, we offer you a 30-day free test access with full functionality and unlimited amount of projects. We would also be happy to advise you and your company on your individual planning.

The german magazine "Giesserei" of the Bundesverbandes der deutschen Gießerei-Industrie reported in detail about inMold in one of the last issues.

Read article